+48 95 762 08 61

Modern technologies of metal working

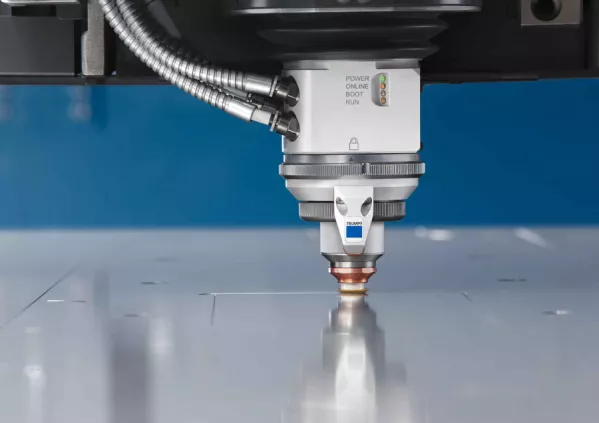

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser technology is based on two constructions: CO2 and fibre. Obviously, both have their advantages and disadvantages. Our company has chosen fibre technology which works perfectly in our plant.

The fibre technology is based on fibre optics, where the imitating beam is amplified by pumping diodes and subsequently routed over a thin fibre optic cable, just like in telecommunications. The best performance of this technology can be observed in the treatment of reflective and thinner metals which require greater precision of materials.

Contrary to gas technology, laser fibre is more efficient; importantly, it consumes 70% less energy. The fibre optic cable does not require as much attention as mirror systems in CO2 lasers. Moreover, it is reliable and maintenance-free and there is no need to worry about replacing components such as fans or filters.

At present, lasers in fibre technology are appreciated for their speed, precision and versatility. In the past, these lasers had problems in cutting thick materials, now this is no problem for a modern laser cutter. Fibre optic technology has become a significant competition for CO2. It is estimated that laser fibre will constitute the basic equipment of any plant processing metals and other materials.

Our Trumpf laser cutting machine with Fibre source of 6 kW TruDisk laser capacity also operates in fibre technology. You can read more about these advantages of our work with the fibre laser on our website under the tab laser cutting.

We invite companies in Poland and abroad to cooperate with our company in the field of modern laser fibre cutting. We guarantee fast and timely processing of orders.

More information can be obtained by calling +48 95 762 08 61 and at our company premises in Strzelce Krajeńskie, ul. Cmentarna 4.

We recommend laser cutting services.