+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

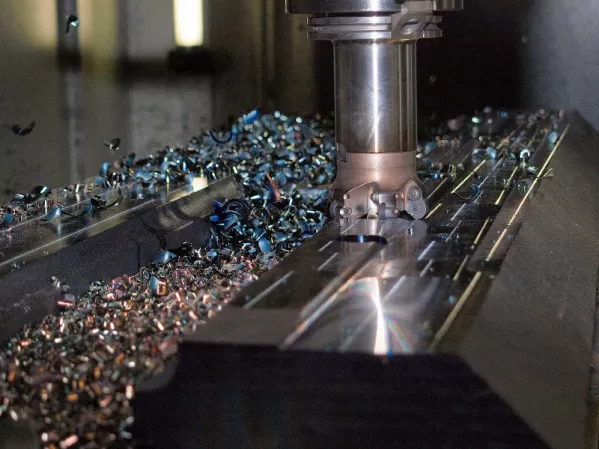

Milling cutters are rotary cutting tools with multiple blades. They are used in milling machines to process flat and shaped surfaces of metal, wood and plastic objects. Their construction allows them to cut various shapes, therefore, depending on their design, we distinguish for example cylindrical, formed, angular, etc. milling cutters. We also distinguish between milling cutters according to the material, thus we have milling cutters made of high-speed steel (HSS), cobalt steel (HSS-E or HSS-Co), powder steel (PM), sintered carbide (HM) or with diamond insert (PKD or DIA).

Milling machines are machines where the main machining tool is a cutter. The main movement that causes the milling cutter to cut is its rotational movement, and also the cutter moves in relation to the work piece. This process is called milling. Today s milling machines are modern, computer-controlled machines that offer advantages such as:

In our plant we also use a modern machining centre by Chiron 23, model FZ 18L of the High Speed series, which perfectly replaces traditional milling machines. The machining area of this centre enables us to mill parts with dimensions of 400x400x2000 mm, while smaller parts are made on machines from the Brother TC-32A and Chiron FZ12 series intended for large batches.

CNC milling is a fast, efficient and economical process. That is why we invite our contractors from all over the country and abroad to cooperate with our company in Strzelce Krajeńskie, ul. Cmentarna 4. For more information, please call +48 95 762 08 61.

We recommend CNC milling.