+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

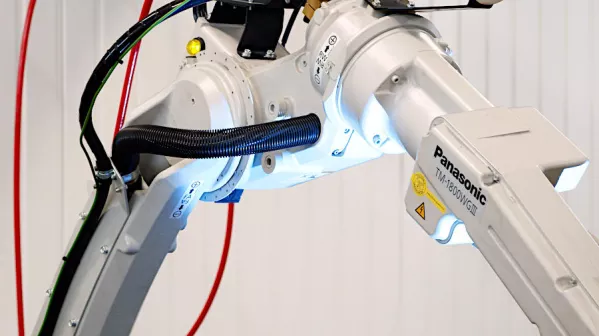

Pro Metal Form, as a leader in the metal processing industry, continually strives for innovation and operational excellence. The introduction of Panasonic welding robots into our production processes has brought key benefits to Pro Metal Form and has significantly impacted the quality, efficiency, and safety of our operations.

Thanks to the Panasonic welding robots, Pro Metal Form has achieved a significant improvement in weld quality, which directly translates into increased durability and aesthetics of our metal products. The precision of the robots allows for high repeatability and minimization of production errors, which is crucial for our clients in the automotive and construction sectors.

The Panasonic robots have enabled us to significantly automate welding processes, thereby shortening the production time of individual components. Reducing machine setup and preparation time allows us to respond faster to market needs and reduce labor and operational costs.

The implementation of welding robots has greatly reduced workers' exposure to hazardous conditions such as UV radiation, sparks, and welding fumes. Automating the most risky aspects of production has enhanced overall safety on the production floor.

With the flexibility of programming the Panasonic robots, Pro Metal Form is also able to undertake custom projects that require special precision and individualized approach, opening up new markets and business opportunities for us.

The deployment of Panasonic welding robots is one of the key elements of Pro Metal Form's development strategy. They not only improve efficiency and quality but also represent an investment in the future of our company, strengthening our market position as a leader in innovative solutions in metal processing. With these robots, Pro Metal Form continually raises industry standards, offering products and services that meet and exceed our clients' expectations.